Green Sand Foundry in India

Machined CI Casting and SG Iron Casting Component Manufacturer

As a leading manufacturer of CI and SG Iron Casting components, we provide our products to both domestic and international suppliers of submersible, centrifugal, vertical turbine pumps, and motors. We aim to provide our clientele with casting components that are strong, pressure tolerant and have a slick surface finish.

At present, the company has gained a reputation for itself in the Pumps manufacturing industry. This has been achieved by their desire to establish high ethics in terms of business operations, vast engineering knowledge and expertise, and a sincere commitment to provide delivery on time and maintain the standards of the quality set. It is this professional approach that has helped us get wide reach across the globe leading us to export products to countries like the USA, Mexico, Argentina, Korea, Italy, Germany, Poland, and Sweden

Green Sand Foundry Capability

Material

- All Grades of Cast Iron

- All Grades of SG Iron (Ductile Iron)

Casting Range

- Range – Weight: 0.5 Kg – 300 Kgs

- Max. Component Size – 600 x 700 x 600mm

Annual Volume

- 60 CR. - 4600 Metric Ton

Value Addition

Foundry

The plant is equipped to produce Grey Iron castings and Ductile iron castings for the customers in the pump industries. Here we produce all grades and varieties of Cast iron and Ductile Iron castings. At present, the production capacity of this plant is around 4500 Metric Ton per year.

An experienced manufacturing company like ours can comprehend the criticality of having an established infrastructure in this industry. That is why we set up different capacity plants, latest technologies, and use equipment that are required to achieve excellence in product creation. Our desire to excel has led to us setting up technologically advanced manufacturing units for the grinding and finishing of our products.

Our company is located at a strategic place near Shiroli, Kolhapur, Maharashtra, India. (400 KM away from Mumbai) and the manufacturing processes for the components like the Grey Cast Iron (CI), Graded Casting and SG Graded Casting are all accomplished here. The aim is to provide only superior quality products to our customers.

The work we conduct is segregated in order to achieve high-grade perfection in results. All the departments have been provided with a supervisor who controls and coordinates the production status of all departments. Having a strong man force and adequate staff ensures that we achieve quality standards while manufacturing the products.

Molding Shop

The Casting of any kind starts with the use of high-quality mold. Thus, we have invested sufficiently in the production of molds which would provide us with castings with excellent finish and high dimensional accuracy.

The sand that is used in these molds has to be exceptionally high quality in the creation of a mold. The latest technology equipment like simultaneous jolt & squeeze molding machine, Polygonal Sievers, Sand Cooler & Intensive Sand Mixers is being used in order to keep the quality level of the sand maintained. The plant uses mechanized sand preparation plants so that we are able to adhere to the standard quality guidelines.

The molding machines that we use are equipped to tackle a varied range of products and gives the customers a cost-effective solution for the product they are looking for.

Melting Shop

We are one of India’s reputed foundries and our per month melting capacity of Iron is around 600 MT. At Siddharth Foundry Services we use the induction melting furnaces to ensure power efficiency and optimum availability of the metal.

CORE SHOP

We at Siddharth group use our wide expertise and facilities in order to manufacture cores as per the customer's needs. Thus, when the customer mentions what they want we can use a balance of precision and optimum utilization of resource to create the product required:

- Cold Box core shooters

- Shell Core Shooters

- No-Bake core making facility

- CO2 core making facility

Quality Control

These days all industries demand that proper adherence to specifications related to materials, processing, quality standards, and delivery is conducted. Keeping these increased demands in mind the Siddharth group follows the quality control guidelines in all its companies. The customers’ requirements are understood and attention is given to the details starting from the query generation to the final delivery of products.

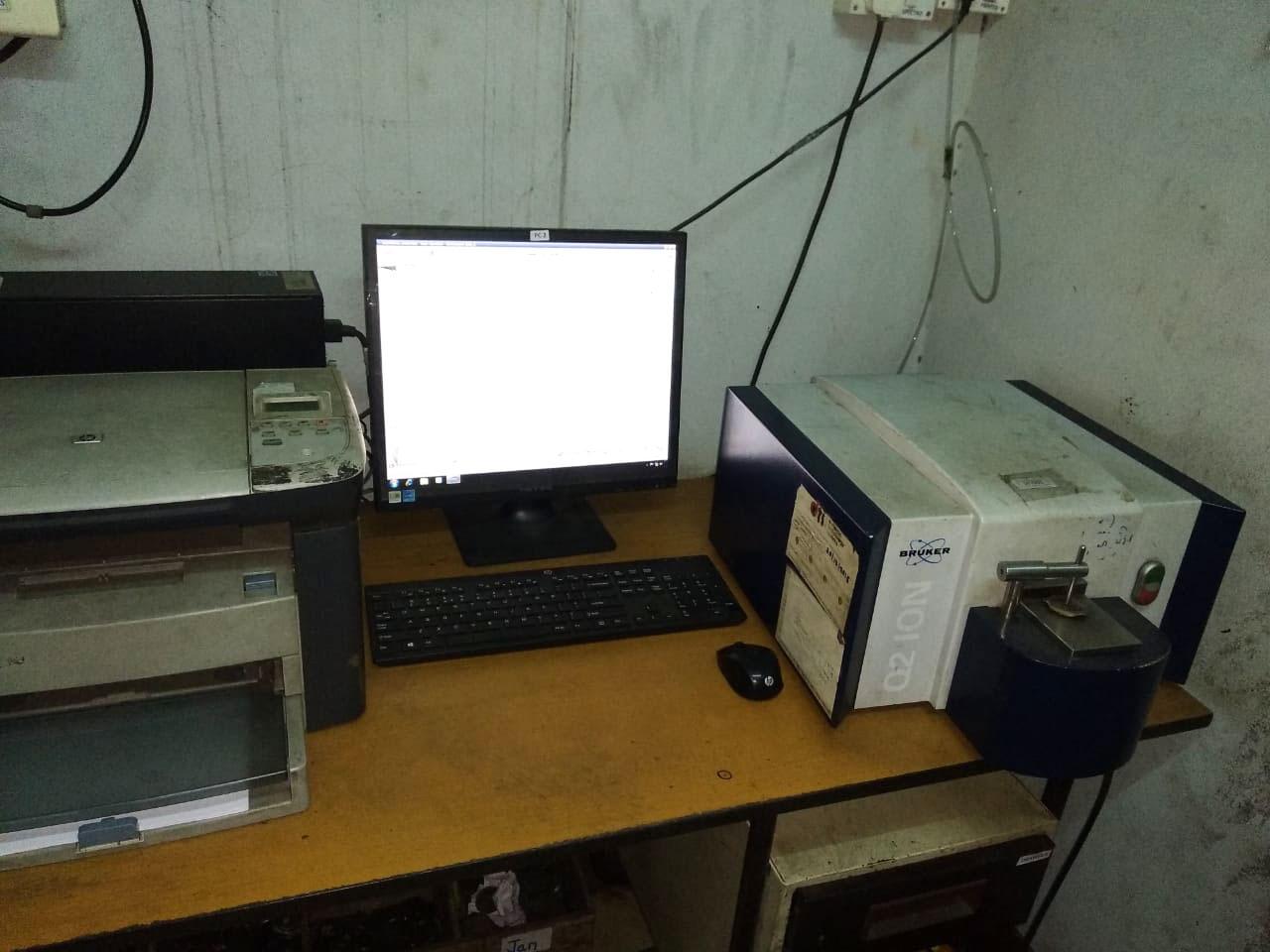

The production processes we pursue are regulated and documented. Using quality audits, the procedures are reviewed and any discrepancies eliminated. The testing equipment we use is calibrated and maintain the international standards of quality. We also have a spectrometer facility that does the chemical analysis of materials using ‘Ttrimos’ and provides accurate measurements of the parts of the machine.

Chemical Analysis

- In house spectrometer with 32 channels.

- All heats poured are tested on-line on Spectrometer.

- All the scrap used is also tested before using it.

- Specimens are stored for a particular period

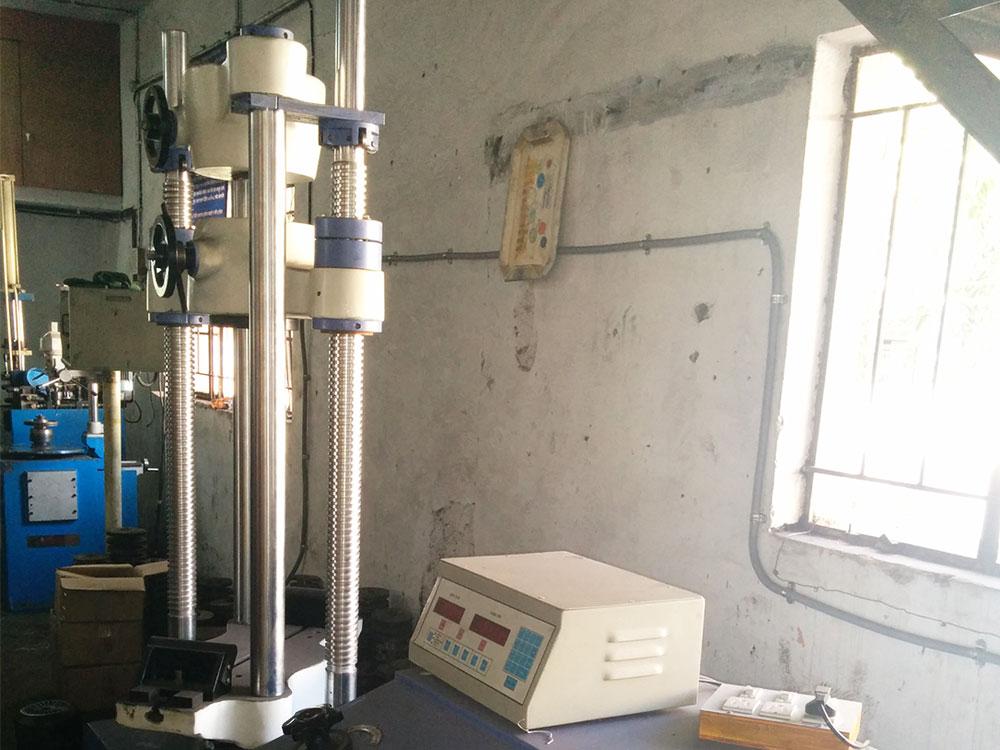

Physical Testing

- In house Universal Testing Machine.

- In house Hardness Testing Machine.

- In house Impact test Machine.

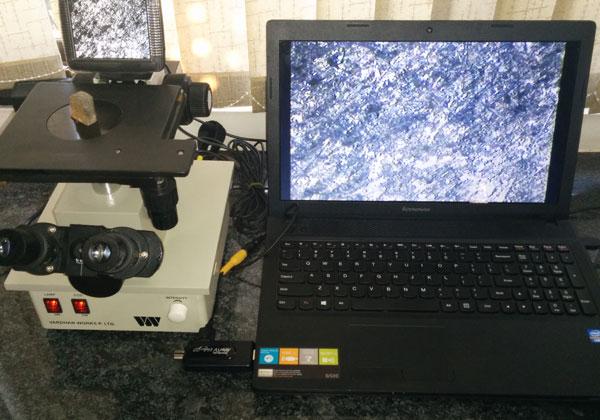

- In house Metallurgical Microscope.

Test Provided

- Chemical Analysis, Tensile Test, Impact Test, Radiography (X-Ray), Dye Penetrate, Corrosion Test, MPT Test, Microstructure.

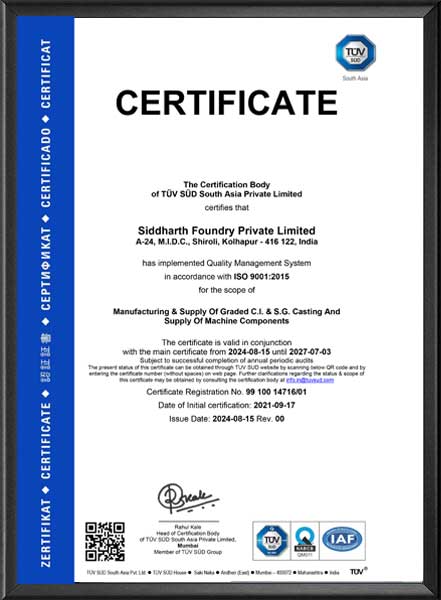

- Castings can also be supplied under third party inspections such as TUV SUD, TUV NORD, BUREAU VERITAS, LLOYDS, and DNV, etc.

Quality checking equipment used at Foundry

- Spectrometer

- Universal Testing Machine

- Digital microscope

- All types of sand testing equipment like Mould hardness, Sand CGS, moisture, compatibility.

- Casting hardness testing machine.

- Digital Pyrometer

- On line Carbon Silicon Analyzer

Pump Casting Components We Manufacture

-

Bearing Bracket

-

Bearing Bracket

-

Bearing Housing

-

Bracket

-

Bracket

-

Housing

-

Casing Cover

-

Casing Cover

-

Volute Casting

-

Centrifugal Pump Componant

-

Centrifugal Pump Componant

-

Centrifugal Pump Componant

-

Centrifugal Pump Componant

-

Motor Stool

-

Motor Stool

-

Impeller

-

Casing

-

Casing

-

Volute Casting

-

Volute Casting

-

Volute Casting

-

Bearing Housing

-

Bearing Housing

-

Bearing Housing

-

Marine Pump Components

-

Marine Pump Components

-

Marine Pump Components

-

Marine Pump Components

-

Marine Pump Components

-

Marine Pump Components

-

Marine Pump Components

-

Marine pump components

-

Pulley With CED Coating

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Casting

-

Motor Base

-

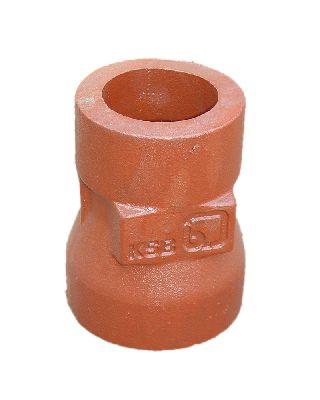

Valve Seat

-

Upper Bracket

-

Bracket

-

Submersible Pump Parts

-

Submersible Pump Parts

-

Motor Stool

-

Submersible Pump Parts

-

Submersible Pump Parts

-

Submersible Pump Parts

-

Submersible Pump Parts

-

Submersible Pump Parts

-

Submersible Pump Parts

-

Submersible Pump Parts

-

Submersible Pump Parts

-

Diffuser

-

Diffuser

-

Diffuser

-

Diffuser

-

Stage Casting

-

Multistage Pump Part

-

Stage Casting with Diffuser

-

Stage Casting with Diffuser

-

Multistage Pump Part

-

Multistage Pump Part

-

Bell

-

Impeller

-

Bowl

-

Volute

-

Volute

-

Breather

-

Breather

-

Head Casting

-

Suction End Cover

-

Product 01

-

Product 02

-

Product 03

-

Product 04

Human Safety

We at Siddharth Group understand the criticality of adhering to the industry standards and thus we work with waste management and see that all the harmful materials are regulated. Apart from that we also ensure to comply with the safety and working condition norms that are necessary to keep the health and security of the employees and humans under consideration.

Awards and Recognition

Since our inception, our aim has been to live up to the changing expectations of our customers. Over the last two decades, we have create our own niche by setting benchmarks in the industry. Here are some of the awards which we have won recently